07GMA-KS40100R | WRENCH, SOCKET 39x41, CLUTCH (FOR TORQUE SPRING NUT, SCOOTER)

Brand : YUMINASHI

- SKU:

- 07GMA-KS40100R

- Availability:

- Usually shipped out on Mondays & Thursdays (Except on Thai public holidays)...

- Weight:

- 450.00 Grams

- Shipping:

- Calculated at Checkout

● YUMINASHI 07GMA-KS40100R | WRENCH, SOCKET 39x41, CLUTCH (FOR TORQUE SPRING NUT, SCOOTER) (07GMA-KS40100R)

● YUMINASHI 07GMA-KS40100R | WRENCH, SOCKET 39x41, CLUTCH (FOR TORQUE SPRING NUT, SCOOTER) (07GMA-KS40100R)

● This scooter clutch socket wrench is 39mm at one side (which is used on almost all Honda, Yamaha, etc scooters), and 41mm at the other side.

● This socket is made of chrome vanadium, which is a type of steel alloy that incorporates chromium and vanadium, offering enhanced strength, durability, and resistance to corrosion and abrasion compared to basic carbon steel.

● KEY PROPERTIES & BENEFITS OF CV (CHROME VANADIUM):

Increased Strength and Toughness:

The addition of chromium and vanadium makes the steel harder and more resistant to wear and tear, making it suitable for demanding applications.

Corrosion Resistance:

Chromium provides protection against rust and oxidation, making chrome vanadium tools suitable for use in various environments.

Abrasion Resistance:

The alloy is less prone to damage from friction and wear, ensuring the longevity of tools.

Hardening Capability:

Chromium and vanadium contribute to the steel's ability to be heat-treated for enhanced hardness, further improving its performance.

● HOW TO USE:

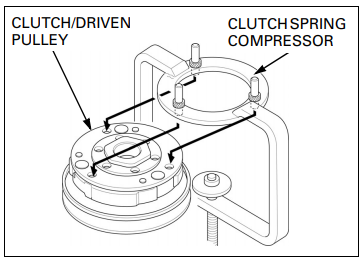

DISASSEMBLY CLUTCH/DRIVEN PULLEY

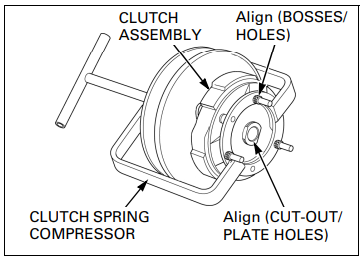

● Set the clutch spring compressor onto the clutch/ driven pulley by aligning the bosses of the compressor with the holes in the clutch.

Hold the clutch/driven pulley by turning the clutch spring compressor clockwise

HONDA Clutch spring compressor 07LME-GZ40201

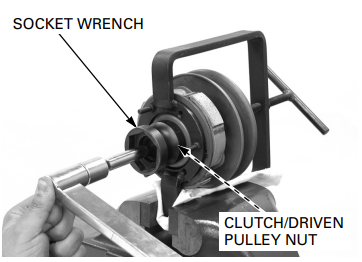

● Hold the clutch spring compressor in a vise.

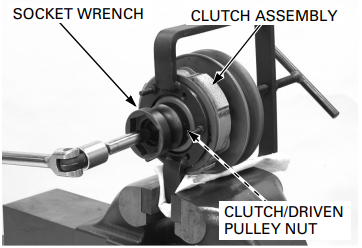

● Remove the clutch/driven pulley nut using the special tool.

● Loosen the clutch spring compressor gradually and remove the clutch assembly

TOOL: YUMINASHI Socket wrench, 39 x 41 mm 07GMA-KS40100R

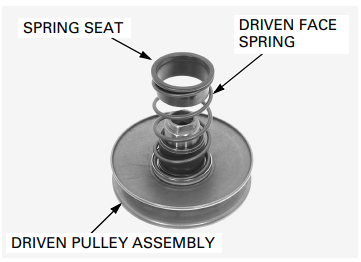

● Remove the following:

– Spring seat

– Driven face spring

– Driven pulley assembly

● Remove the following:

– Spring cap

– Spring cap seat

ASSEMBLY CLUTCH/DRIVEN PULLEY

● Set the clutch assembly to the driven pulley. Set the clutch spring compressor over the clutch/ driven pulley assembly aligning the bosses of the compressor with the holes of the clutch. Compress the driven face spring while aligning the cut-out of the pulley nut threads with the drive plate hole and install the clutch/driven pulley nut.

● Hold the spring compressor in a vice.

● Tighten the clutch/driven pulley nut to the specified torque using the socket wrench.

TORQUE: 54 N·m (5.5 kgf·m, 40 lbf·ft)

● Remove the spring compressor from the clutch/driven pulley assembly.

![]() SMART SHOPPER TIP:

SMART SHOPPER TIP:

※ BUYING MORE THAN 1 PIECE CUT THE TRANSPORT PRICE, AND YOU RECEIVE A 10% DISCOUNT ON TOP OF IT!

※ B2B:

- Purchases between 2 & 4 pieces of this product will receive a 10% DISCOUNT

- Purchases between 5 & 9 pieces of this product will receive a 15% DISCOUNT

- Purchases between 10 & 19 pieces of this product will receive a 20% DISCOUNT

- Purchases between 20 & more pieces of this product will receive a 25% DISCOUNT

- Click Here if you would like to know how to check the shipping fee for your order...

Thai Baht

Thai Baht

US Dollar

US Dollar

Euro

Euro

Pound Sterling

Pound Sterling

Japanese Yen (¥)

Japanese Yen (¥)

Australian Dollar

Australian Dollar

Canadian Dollar

Canadian Dollar

Russian Ruble

Russian Ruble

Indonesian Rupiah

Indonesian Rupiah

Malaysian Ringgit

Malaysian Ringgit

Polish Złoty

Polish Złoty

Czech Koruna

Czech Koruna

Brazilian Real

Brazilian Real

South African Rand

South African Rand

Philippine Peso

Philippine Peso

South Korean Won

South Korean Won

Indian Rupee

Indian Rupee

Vietnamese Dong

Vietnamese Dong

Israeli Shekel

Israeli Shekel

Singapore Dollar

Singapore Dollar

CFP Franc

CFP Franc

Swiss Franc

Swiss Franc

Swedish Krona

Swedish Krona

Turkish Lira

Turkish Lira