12100-K0S-V62R | 167CC / 62MM GT4S HEAD CYL. KIT, HIGH COMPRESSION (125/150/160 eSP+ 4V ENGINES)

Brand : YUMINASHI | GT4S

- SKU:

- 12100-K0S-V62R

- Availability:

- Usually shipped out on Mondays & Thursdays (Except on Thai public holidays)...

- Weight:

- 1,300.00 Grams

- Minimum Purchase:

- 1 unit

- Shipping:

- Calculated at Checkout

● 167CC GT4S CYLINDER KIT, HIGH COMPRESSION (eSP+ 125CC/150/160 ENGINES) (12100-K0S-V62R)

● 167CC GT4S CYLINDER KIT, HIGH COMPRESSION (eSP+ 125CC/150/160 ENGINES) (12100-K0S-V62R)

● The STD Ø20/17mm valve size from the eSP+ 125cc and 160cc engines come from the 2015 4-Valve FORZA125 EURO-4 engines, and HONDA didn't change the valve size when they increased the cylinder capacity from 125cc to the 160cc eSP+ engines.

● So if these valves were designed for 125cc engines, then it's not a bad idea to take a look to upgrade the valve size to use a 60mm or larger piston size.

● CALCULATION / COMPARISON 2V vs 4V:

● If you have experience with the old 2-Valve engines, then this will make it easy for you to compare the valve size, because we know that the STD Ø22/27mm valves from the 2-Valve PCX125 engine did a great job, and the STD Ø23/29mm valves on the 2-Valve PCX150 engine with stock a 58mm piston, could handle easy a 60mm piston.

● If we take a look to the surface area for 2 times Ø20mm intake valves, then we get 2 times 314.6mm² which equals 628.32mm², and this equals 1 intake valve of Ø28.28mm.

If we do the same for the exhaust valves, then the surface area of 2 times Ø17mm valves equals 103.76mm², or 1 exhaust valve of Ø24.04mm.

So based on this calculation we get a single Ø28.28mm intake valve as result, and this is larger compared to the formal PCX125 Ø27mm intake valve, but it's actually smaller compared to the formal PCX150 Ø29mm valve with the 58mm piston.

2 exhaust valve of Ø17mm equals a single Ø24.04mm exhaust valve, and this is larger as the earlier single Ø22mm 125cc, and Ø23mm 150cc exhaust valve.

● SOLUTION:

● By installing the YUMINASHI GT4S CYLINDER HEAD (LINK) and this 62mm GT4S CYLINDER KIT (12100-K0S-V62R) with the flat piston, you're not only getting a 167.47cc engine instead of a 125cc engine, but you are getting 2 larger Ø22mm intake valves, and 2 larger Ø19mm exhaust valves with a higher compression ratio piston.

● 2 Intake valves of Ø22mm equals a single Ø31.11mm intake valve, and 2 exhaust valves of Ø19mm equals a single exhaust valve of Ø26.87mm.

Based on the Dyno results we see that we can use a 32mm and 34mm throttle body in combination with this GT4S Cylinder Head on the 62mm bore.

※ If you have a 160 engine (which is called 150 in the US), then you don't need to order the entire cylinder kit to run the big valve GT4S head, you can just order the GT4S head together with the GT4S 60mm piston (LINK) and install it on your stock cylinder with a new head gasket (LINK)...

※ This cylinder head need to be installed with the large diameter cylinder gasket (LINK), and recommend to install a exhaust header with 28mm inner diameter.

※ Recommend to install a 32mm throttle body & manifold set.

※ The injector flow rate will depend on which type of exhaust you are installing, with the stock exhaust the injector flow rate will be much smaller compared to a sports exhaust installed.

※ Recommend to use MOTUL SCOOTER POWER LE and SCOOTER EXPERT LE 4T 10W-40 (5W-40 if you drive in temperatures below 0°C.)

![]() Torque Spec for the cylinder head nuts are: Torque 27 N m (2.8 kgf m, 20 lbf ft)

Torque Spec for the cylinder head nuts are: Torque 27 N m (2.8 kgf m, 20 lbf ft)

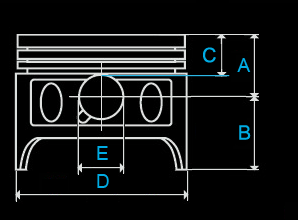

● PISTON DETAILS:

● The piston you get in the 160cc YUMINASHI GT4S high compression kit is not only a higher then the stock 160 piston with larger valve pockets for the GT4S cylinder head, but also a lighter piston compared to stock, where the valve pockets are prepared to run a high lift performance camshaft.

● The hard chromium plating layered (Cr) piston rings which come with the set are produced by very strict Japanese standards and has excellent characteristics which combine the original properties of chromium metal with the advantages of erector-deposits!

The main benefits from the chrominum plating layered piston rings are extremely high hardness of HmV (Micro Vickers), 800 to 1100 (cf. gray cast iron 220 to 270), high melting point of approx. 1800°C (cf. cast iron 1200°C), good thermal conductivity and corrosion resistance, a low friction factor and excellent wear resistance, such features are very effective in preventing piston ring wear.

● The enlightened piston is made from A-grade materials and the piston skirts come with a molybdenum coating. The Anti-detonation grooves on the top ringland provide several advantages, which include further atomization of the combustion charge to prevent damage to the piston and ring caused by pre-ignition. These grooves also prevent carbon build up on the ring land which can cause the compression ring to stick in the ring groove.

The pressure seal groove will prevent gas build up below the top compression ring; these gases can cause the ring to lift from the ring groove. Unseating of the ring will result in compression losses and lower performance.

● THIS 168CC CYLINDER KIT IS THE CORRECT KIT TO BE INSTALLED ON THESE eSP+ ENGINES:

● 125CC 4V eSP+ (STD BORE X STROKE= 53.5MM x 55.5MM):

- FORZA125 (2021- )

- GIORNO+ 125 (2023- )

- LEAD 125 (2022- )

- PCX125 (2021- )

- SH125i (2020- )

- SH125 MODE (2021- )

● 150/160CC 4V eSP+ (STD BORE X STROKE= 60MM x 55.5MM):

- ADV160 (2022- )

- AIR BLADE 160 (2022-)

- CLICK 160 (2021- )

- PCX150 (USA) (2021- )

- PCX160 (2021- )

- SH150i / 160 DIGITAL SOHC (2020- )

- STYLO 160 4V (2024- )

- VARIO 160 (2021- )

● 60MM FLAT HIGH COMPRESSION PISTON SPECIFICATIONS: (CHECK BEFORE YOU ORDER!)

- A= 21.08MM

- B= 16MM

- C= 14.08MM

- D= 59.95MM

- E= 14MM

● 62MM BORE GT4S INGREDIENTS SHOPPING LIST:

- 62MM GT4S Cylinder Kit | 12100-K0S-V62R

- GT4S 22/19mm Cylinder Head | 12200-K2S-GT4S | LINK

- GT4 SUPER Sports Camshaft | 14100-K0S-GT4 | LINK

- 34MM GT4S Head Throttle Body & Manfifold Set | 16410-K0R-34GT4 | LINK

- 170CC B-Type Injector | 16450-B08-5ED | LINK

- 45MM-51MM Stainless Hose (Size 2) With 90° & Straight Connector (※ ADV160 | CLICK160 | PCX125/160 ONLY) | 17570-K1Z-252 | LINK

- VARIATOR & GEAR SPROCKETS:

- ADV160: STD Torque Control Variator Set | 22110-K1Z-J10S LINK | 14/43T Final Drive Gear Set LINK (NO SHAFT) / LINK (WITH SHAFT) | MOTUL-F875 Gear Oil LINK

- CLICK160/VARIO160: 14T Torque Control Variator Set LINK

- PCX125: STD Torque Control Variator Set | 22110-K1Z-J10S LINK | 15/43T FINAL DRIVE GEAR SET LINK (NO SHAFT) / LINK (WITH SHAFT) | MOTUL-F875 Gear Oil LINK

- PCX160: STD Torque Control Variator Set | 22110-K1Z-J10S LINK | 14/42T FINAL DRIVE GEAR SET LINK (NO SHAFT) / LINK (WITH SHAFT) | MOTUL-F875 Gear Oil LINK | SPL Speed Sensor LINK - 1500RPM TRE-Torque Spring Set | Yellow Spring | 23233-K1Z-TRE2 | LINK

- EXHAUST:

- ADV160: Sound Adjust Stage-2 Exhaust System & Heatshield Combo | 18300-K1Z-SA2C | LINK (※ CAN ONLY BE INSTALLED WITH 1 OF THE 3 BOLTS ON ADV160)

- CLICK/VARIO160 | PCX125/160: YUMINASHI Sound Adjust Stage-2 Exhaust System | 18300-K1Z-SA2 | LINK

![]() SMART SHOPPER TIP:

SMART SHOPPER TIP:

※ BUYING MORE THAN 1 PIECE CUT THE TRANSPORT PRICE, AND YOU RECEIVE A 10% DISCOUNT ON TOP OF IT!

※ B2B:

- Purchases between 2 & 4 pieces of this product will receive a 10% DISCOUNT

- Purchases between 5 & 9 pieces of this product will receive a 15% DISCOUNT

- Purchases between 10 & 19 pieces of this product will receive a 20% DISCOUNT

- Purchases between 20 & more pieces of this product will receive a 25% DISCOUNT

- Click Here if you would like to know how to check the shipping fee for your order...

Thai Baht

Thai Baht

US Dollar

US Dollar

Euro

Euro

Pound Sterling

Pound Sterling

Japanese Yen (¥)

Japanese Yen (¥)

Australian Dollar

Australian Dollar

Canadian Dollar

Canadian Dollar

Russian Ruble

Russian Ruble

Indonesian Rupiah

Indonesian Rupiah

Malaysian Ringgit

Malaysian Ringgit

Polish Złoty

Polish Złoty

Czech Koruna

Czech Koruna

Brazilian Real

Brazilian Real

South African Rand

South African Rand

Philippine Peso

Philippine Peso

South Korean Won

South Korean Won

Indian Rupee

Indian Rupee

Vietnamese Dong

Vietnamese Dong

Israeli Shekel

Israeli Shekel

Singapore Dollar

Singapore Dollar

CFP Franc

CFP Franc

Swiss Franc

Swiss Franc

Swedish Krona

Swedish Krona

Turkish Lira

Turkish Lira